Precision Farming Planting & Seeding

Early Riser Planters

DeltaForce® Hydraulic Downforce

Automatically adds or removes weight on the gauge wheels for target weight on gauge wheels allowing for consistent depth control in all soil conditions and speeds

Advanced Seed Information (ASI)

Advanced Seed Information (ASI) option gives you detailed seed placement information, which monitors seed for planting performance feedback.

Key Features include:

- Shows readings for singulation, skips, multiples, Seed Release Index (SRI), and good spacing

- User sets row readings – set for all rows, high row, low row, or average

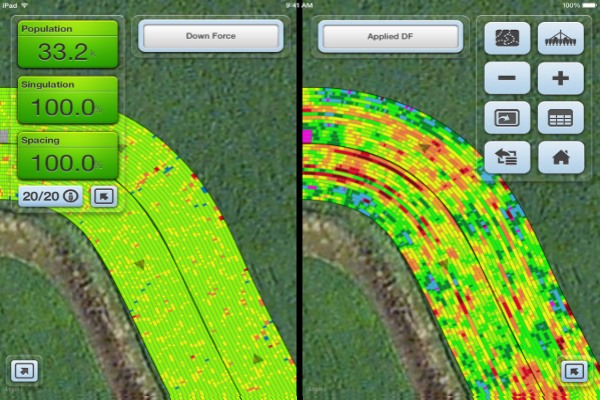

FieldView Cab App

App offers high-definition mapping for row-by-row performance feedback.

- Data delivered to cloud for access anywhere

- Scouting tool for planter feedback and yield impacts

- Connects planter data to harvest data (for combines equipped with YieldSense)

- Planter Performance Mapping - Planter performance metrics, including Advanced Seed Information (ASI), down force, alternator metrics, and others, are visible through the Pro 700 and Desktop Software.

CleanSweep® Air Cylinders For Row Cleaners

Quickly and easily adjust row cleaner ride from the AFS Pro 700 display

vDrive

vDrive takes the place of both a drive system and clutch.

It plants the population you set, and no more. With these motors, you can control each row of your existing planter individually: precisely executing variable rate prescriptions, planting correct populations around curves, and utilizing automatic row-by-row shut-off on point rows, avoiding double plant.

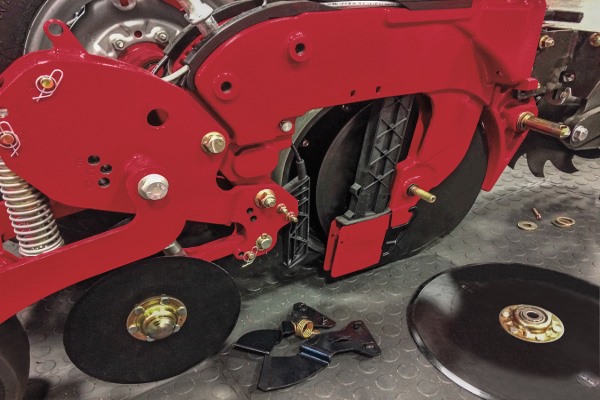

vSet 2

The vSet® 2 Vacuum Seed Meter was co-developed with Case IH and Precision Planting engineers specifically for the Early Riser planter. This meter, combined with vDrive® electric drive, ensures precise per-row seed metering with simplicity and less maintenance. The mini-hopper's or on-row hopper's single air-intake screen is easy to access and clean. In fact, the entire seed meter offers fast, easy and, yes, tool-free maintenance and adjustments – even when switching between crops

Advanced Seed Meter

Advanced Seed Meter (ASM) with AccuDrive provides proven accurate seed placement with trouble-free service - delivering higher yield potential at faster operating speeds.

mSet

mSet - mSet pairs with Precision Planting's 20|20, vSet meter and vDrive electric drive. Under a split hopper holding two hybrids, a seed selector lets a few seeds of the hybrid that is currently being planted into the meter. When it is time to switch hybrids, it allows seeds from the other part of the hopper to come into the meter. A seed level sensor in the meter tells the seed selector when more seed is needed and ensures that you don't run out of seed.

Advanced Seed Delivery - SpeedTube

The Advanced Seed Delivery™ (ASD™) option delivers the highest level of seed placement accuracy. This includes the Precision Planting SpeedTube, which uses a flighted belt to control the delivery of the seed from the meter to the furrow, eliminating the drop and tumble variability of traditional gravity drop tubes at speeds up to 10 mph.

In-Cab Closing Adjust

Set and fine-tune closing system quickly and easily from the AFS Pro 700 for the field conditions

Wing-Downforce (2130, 2140, 2150)

- Stabilize wings at high speeds

- Maintains depth control on wing row units in challenging conditions

Factory Liquid Fertilizer System

- 3 section control with row by row shut-off option

- Factory in furrow delivery or 2x2 UMO delivery

Seed Tube – WaveVision

The Seed Tube option is optimized for accuracy at faster planting speeds, using DICKEY-john® Hy Rate Plus 10 LED self-calibrating seed sensors for accuracy in a range of seed sizes and field conditions.

Precision Air Cart

AccuSection™ Control System

The patented and exclusive AccuSection Control (ASC) system helps you get the most out of your inputs and enhance yield characteristics by shutting off rows or sections to avoid over-seeding and over-application of fertilizer. Using AFS AccuGuide™ autoguidance, the system turns off air drill sections automatically when you enter areas that have already been seeded, or at headland turns, point rows, 'prairie ponds', and sloughs. Growers who have upgraded spraying equipment to include section and nozzle control systems have realized savings on product use – ranging from 7 to 15 percent.

Intelligent Ag Wireless Blockage

The Recon Wireless Blockage and Flow Monitor provides reliable, versatile machine monitoring technology to improve precision in every pass. Unlike traditional optical sensors, our patented acoustic sensors monitor the sound of the seed flow so you can depend on accurate readings even if the sensors get dusty. The system is easy-to-install and can adapt to nearly any brand of equipment for a variety of applications. Its software is compatible with your iPad to provide a simple, user-friendly interface that displays all manifold runs and gives you an audible alert if a run becomes blocked.

Say goodbye to dust-covered optical sensors. The acoustic sensors in your Recon Wireless Blockage and Flow Monitor function like a stethoscope, instantly detecting blockages or reduced seed flow, anywhere on the implement.

Multiple sensor options allow the system to easily adapt to nearly any rig or application:

- Bourgault, Case IH, John Deere, Seed Hawk, Amity, Sunflower, Horsch, Flexi-Coil and more

- Multiple Product Types and Rates

- Dry Fertilizer Applicators, Deep Banders, and Strip-Till Units

- Dual-Shooting and Mid-Row Banders

Precision Disk

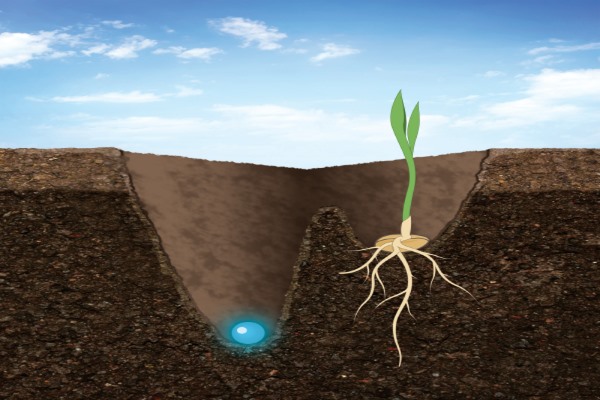

Precision Placement Knife

The new Precision Placement Knife™ allows for separate placement zones for the seed and fertilizer. It is a new concept; different from other manufacturers.

The precise Fixed Placement technology provides consistent placement of the seed and fertilizer in the seed trench. Agronomically, placing fertilizer directly in the root zone at the time of seeding saves a trip through the field and incorporates the fertilizer on the go.

Case IH's Fixed Placement ensures that when fertilizer is placed in the soil, the seed is placed 1 in. up and 1 in. to the side no matter where the row unit goes.

This makes the nutrient zone close enough to the seed row for excellent access yet far enough for seed safety. In addition, tight turns or side-hill drafting never affects this placement.

High Plains Equipment is conveniently located near the areas of Grand Forks, Casselton, Bismarck, Jamestown, Minot and Langdon.