Precision Farming Application Controls

AIM Command FLEX

AIM Command FLEX advanced spray technology precisely controls product flow and spray pressure to optimize application rate, spray coverage and accuracy over a range of speeds and field conditions. This new system delivers the ultimate in sprayer control to help you get the most out of every tank, every hour and every acre.

- PWM-Pulse Width Modulation ensures constant application rate and pressure even as speed changes

- 36 virtual boom sections helps reduce over-application

- On-demand Drift Control- pre-set two spray pressures to toggle between while spraying

- Compensates for turns – Each nozzle adjusts for speed of the boom during field curves and turns

- Instant on/off – target rate is reached immediately after nozzles are turned on

- Nozzle valve diagnostics alerts you immediately if a valve quits working or a wire becomes unplugged.

AccuBoom

AccuBoom automatic boom section control automatically turns off boom sections when the sprayer enters an area that has already been sprayed and then turns the sections back on when leaving the applied area

AutoBoom

- AutoBoom automatic boom height control detects changes in terrain and adjusts the booms accordingly.

- This decreases operator fatigue and wear and tear on the machine and increases the accuracy and coverage of the applications.

- Configure your AutoBoom system with additional ultrasonic sensors or gauge wheels to maintain a level spray platform. This will provide the best possible application and maximize boom life.

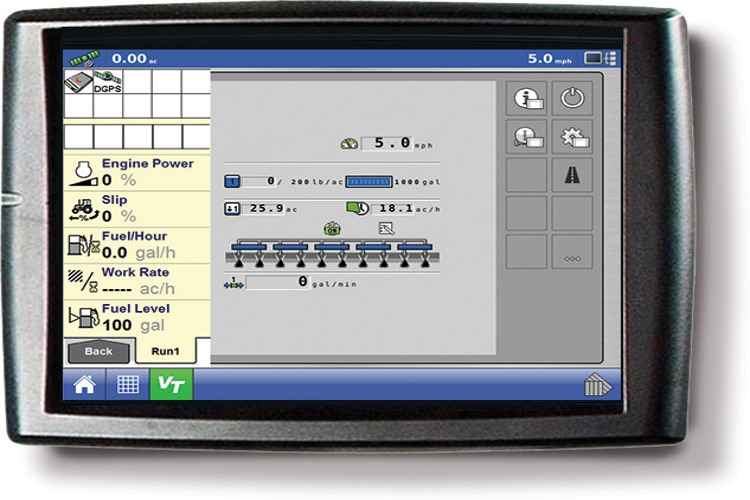

AFS Product Control

AFS ISOBUS Product Control lets you view your implement on your ISO compliant display via a virtual terminal and control your implement's necessary functions at the touch of a finger.

Compatible with these ISO enabled displays, AFS®ISOBUS Product Control supports a variety of field applications, making it a great solution for the mixed fleet grower.

- Case IH Pro 700

- New Holland IntelliView™ IV

- John Deere 2630

- John Deere Generation 4

- Mueller TOUCH800® and TOUCH1200®

- Ag Leader Integra

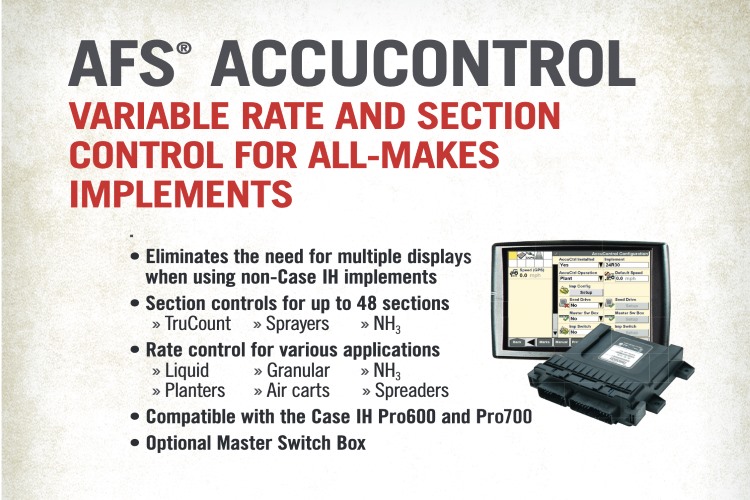

AFS AccuControl

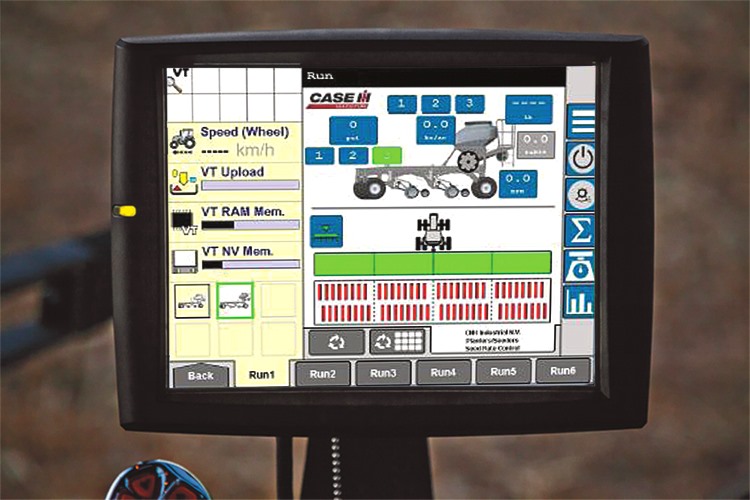

The AFS AccuControl crop input control system is a variable rate and section control system that utilizes the AFS Pro 700 display. Case IH AFS AccuControl manages a wide variety of applications, such as seed monitoring and mapping, auto section control, variable rate control, and more.

This single display solution connects a Case IH tractor to a non-Case IH implements, such as sprayers, strip till applicators, NH3 applicators and up to 48-row planters.

- Controls seed and liquid up to four sections and up to 48 rows for individual row shut off; manual configuration of section and row orientations and variable rate seeding at up to four different section rates for better management of inputs

- Sprayers; strip till applicators: Controls up to 48 boom sections; single-product variable rate control

- NH3 applicators: Controls up to 48 sections; single-product variable rate control

- Coverage logging: Track and map; coverage with any implement

Field IQ

The Field-IQ crop input control system is a variable rate and section control system. It prevents seed and fertilizer overlap, controls the rate of material applications and monitors seed delivery. Field-IQ™ automatic section control can control up to 48 individual rows, eliminating waste and double applications of inputs by automatically shutting off rows or sections in areas, which have already been covered.

ISOBUS Task Controller

AFS ISOBUS Task Controller can be used to control any ISOBUS-compliant implement using the AFS Pro 700 display. Task Controller allows for automated section control, variable rate application, mapping and more on compatible implements, from planters and seeders to sprayers and combines.

Automatic section control uses mapping to prevent over- or under application of fertilizer, pesticides and other inputs.

Variable rate technology allows prescription application of inputs.

Variety tracking lets you track and map up to 30 seed varieties per field during planting. The technology matches seed varieties with yield and moisture data to help you accurately analyze variety performance.

As-applied mapping records exactly what you're applying and generates a map for future analysis.

High Plains Equipment is conveniently located near the areas of Grand Forks, Casselton, Bismarck, Jamestown, Minot and Langdon.